The use of electric motors in modern society is staggering. It is estimated that motor systems alone account for 47% of the world's electricity consumption. Additionally, in a manufacturing environment, industrial motor systems account for 70% of all electricity consumption.

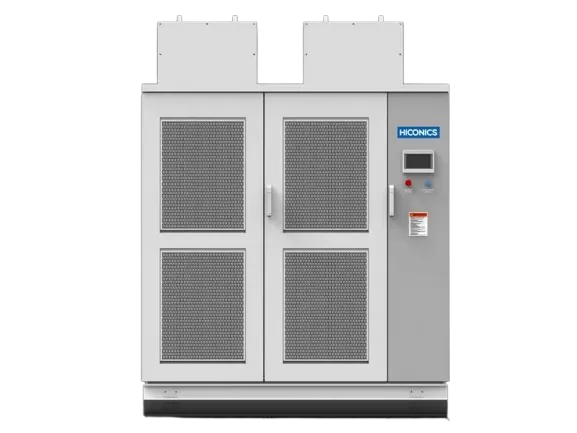

Intersecting this reality is the fact that, as software, artificial intelligence, cloud-based systems and other advanced forms of technology continue to develop, opportunities exist to improve the performance and efficiency of industrial motor systems through monitoring, automation and more precise management . whole system. Today, the norm is to connect the control of these motors throughout the ecosystem to run production lines at scale and provide better performance for the entire system. Let Hiconics VFD manufacturer explore for you.

A variable frequency drive (VFD) is a device that converts a fixed AC voltage and frequency into an adjustable AC voltage and frequency. It is used to control the speed of the AC motor. By adjusting the voltage and frequency, an AC induction motor can run at many different speeds. Variable Speed Drives (VSDs) are simpler to design and use, but the ability of VSDs to control the speed of AC and DC motors is universal. They are ideal for stand-alone applications as they mainly consist of a motor and a control unit. So what is the difference between VSD and VFD?

Variable speed drives control speed independent of torque. Therefore, the ability to change the system that affects their operation is limited to the speed adjustment of that motor. What is the difference between VSD and VFD in terms of process control? Compared to VSDs, VFDs offer several advantages in optimizing process control for increased efficiency and overall operational excellence.

What makes the difference between VSD and VFD is system optimization: because the VFD is connected to the entire system, it can send and receive data on system components. It can also send commands and control the behavior of these elements. As mentioned earlier, VFDs can control dampers, actuators, and many other machine components and other motors to always set the system for optimum performance.

The difference between VSDs and VFDs is in communication: Because VFDs can use a common communication protocol, they can collect and analyze data, allowing them to change operating parameters through a programmed set of responses. This might include things like slowing or stopping equipment for safety reasons, preventing damage, or locating the exact location of a failure interruption and sending alerts to the right technicians.

What differentiates VSDs and VFDs is in connectivity and the Industrial Internet of Things: As the concept of the connected factory evolves through technological improvements, additional software can be added to optimize vibration damping or identify maintenance issues before they arise. These and many other advantages make VFDs a stronger choice than simple VSDs in process control. Contact Hiconics to discuss your VFD needs and let us assist you in implementing effective and sustainable solutions for your projects.