In the modern shipping industry, especially in the tugboat sector, the demand for promoting energy saving and emission reduction is increasing. Although traditional diesel engines are widely used, they are less efficient and highly polluting. Therefore, more and more tugboats are beginning to adopt new energy technologies such as electric, hybrid, and even hydrogen fuel cells for propulsion. Liquid-cooled VFD (variable frequency drives) is becoming an important trend in these new energy tugboats, playing a key role in improving ship efficiency and reducing environmental impact.

Liquid-cooled VFD applications in new energy tugboats demonstrate its outstanding performance in complex environments. Compared to traditional air-cooling methods, liquid-cooled VFD has significant advantages, especially under the harsh conditions of the shipping industry, such as enclosed, high temperature, high salt, high humidity, and densely packed electrical equipment environments. These conditions require liquid-cooled VFD to have a higher protection grade and innovative cooling methods to ensure equipment reliability.

Liquid-cooled VFD effectively reduces the impact of harsh environments on the equipment through a liquid cooling system. Its innovative cooling technology not only enhances the durability of the equipment but also allows liquid-cooled VFD to operate stably in high temperature and high humidity conditions. This cooling method can significantly increase the power density of the inverter, save space and weight, thereby enhancing the transportation capability of the vessel. For new energy tugboats, the application of liquid-cooled VFD not only improves the system's efficiency but also optimizes the overall design of the ship, providing more space utilization solutions.

Liquid-cooled VFD takes on several important roles in new energy tugboats, including driving the propulsion motor, controlling the speed-variable generator for power generation, managing the charging and discharging of energy storage devices, providing AC power grid electricity, and connecting to shore power. The structural design of liquid-cooled VFD fully complies with the technical requirements of marine DC switchboards and inherits all the functions of electric propulsion inverters.

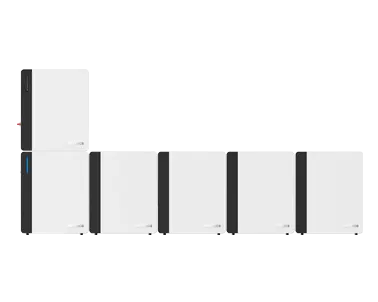

The innovative structure design of liquid-cooled VFD makes its maintenance and upkeep work in vessel applications more accessible. Its modular design allows the equipment to be flexibly installed in limited spaces and achieve high power output through parallel connection, enhancing the redundancy of the equipment. This design not only reduces the risk of failure but also decreases the variety and cost of spare parts, providing more flexible solutions for system integrators.

The application of liquid-cooled VFD in hybrid electric tugboats signifies the broad prospects of inverter products in the field of new energy tugboats. Liquid-cooled VFD not only enhances the environmental friendliness and efficiency of the vessels but also promotes the shipping industry towards a greener and more efficient direction. With continuous advancements in technology, liquid-cooled VFD will demonstrate greater potential in the application of new energy tugboats, bringing more innovative solutions to the shipping industry.

In summary, the application of liquid-cooled VFD in new energy tugboats is not only an inevitable trend in technical development but also an effective means to address environmental challenges. Its efficiency, stability, and eco-friendly characteristics make it an indispensable component of future marine power systems. With increasingly stringent requirements for environmental protection and energy efficiency, liquid-cooled VFD will play a more crucial role in the future shipping industry.